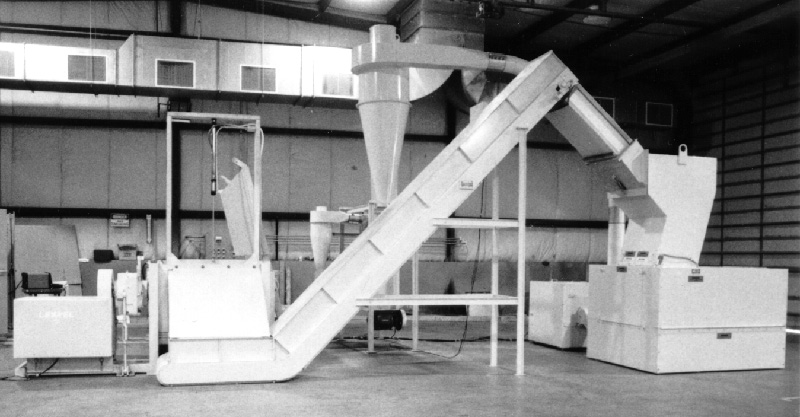

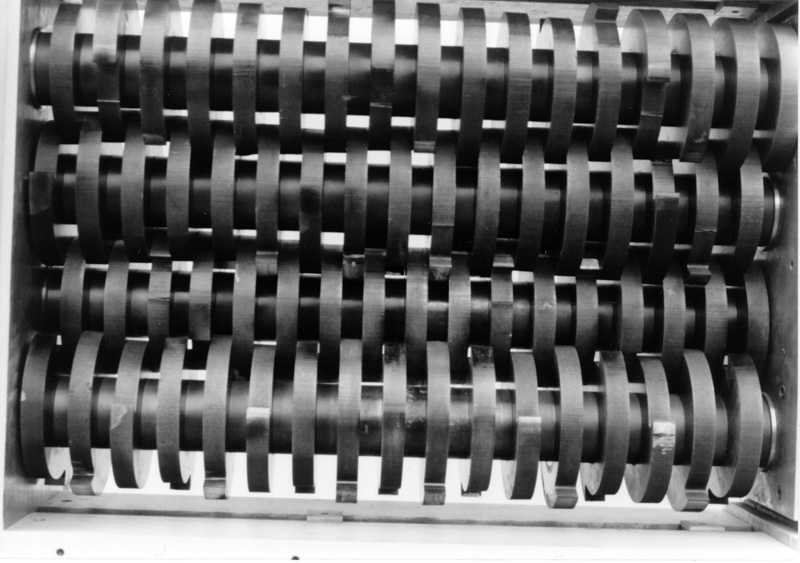

Applicon builds custom systems to process high value or very abrasive raw materials with minimum wear to the system and minimum contamination to the product.

Circuit designs can include:

Tramp metal detection and removal

Screening and recirculation after primary crushing

Screening and recirc after tertiary crushing

Air separation of fines after tertiary crushing

Volumetric or gravimetric feeding to optimize throughput

Amperage controlled feed to all crushers with PID loop control

Micronization

Screening to produce multiple greaded finished products

Impact milling for low abrasion products, in lieu of or ahead of jet milling

AIM-Jet fluid bed fluid energy pulverizers for zero iron contamination

Inert gas or hot gas

Systems for production of fine granules to ultra fine powders, for Chemicals waxes, pigments, powder coatings, cosmetic ingredients Refractories, catalysts, ceramics Mineral fillers