Cylindrical body for applications:

• With all material loaded by conveyor

• For vacuum loading

• For vacuum degassing, inert atmosphere, and drying

• For containment of volatiles

• For high speed or high shear blending

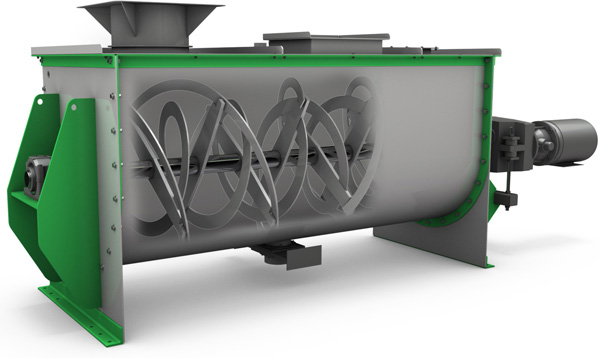

U-tub body for applications that require:

• The most compact blender, for use in a congested plant area

• Manual loading hatches for minor ingredients

• Swing up covers for sanitation between dissimilar recipes

• Lower speed blending to reduce impact and/or frictional heat

• Single or double inner, and outer, ribbons

Capacities from 30 to 440 cu.ft. working volume

Jacketed body for non-contact heating or cooling:

• Hot or chilled water

• Steam to 150 psig

• Thermal fluids

Construction Features & Options

• 304 or 316 stainless

• Sanitary internal finish

• Abrasion resistant paddles and arms

• Clad agitator shaft

• Clad end plates

• Removable end plate(s)

• Removable agitator via stub shafts

• Spray nozzles or header for liquid additions

• Plug style swing gates to eliminate idle (unmixed) pockets

• Gas purged seals for abrasion resistance or sanitary applications

• Single inner & outer ribbon (most common)

• Double inner and outer ribbons (ribbons at 180°) for fastest blend or least re-segregation

• Close clearance from ribbons/paddles to body, for thorough cleanout

• Extra heavy construction for long service life

• Round or plate style supports for ribbons or paddles, gusseted for strength